CANNING LIGHT CHERRIES

AT MUIRHEAD CANNING CO.

1. We receive the fresh fruit in bins from the growers. These are Rainier cherries. Each bin of cherries yields about 500 cans (28oz size).

2. A bin is loaded onto the bin dumper and the cherries are, well, dumped.

3. Then they drop onto a conveyor that leads them up to the canning line.

4. The cherries are then sorted by hand.

5. The ones that don't make the cut travel down a chute into the waste removal system (aka the wheelbarrow).

6. All the high quality cherries travel down the belt too...

7. These lovely ladies hand fill the cans. Look how full they load those cans!

8. The cans then file into our kids' favorite machine: the syruper. Each can is filled with a warm syrup of pure cane sugar and water (or just plain water).

9. The filled cans head into the exhaust box where they are jostled a bit to remove air bubbles and some added heat starts to warm them up.

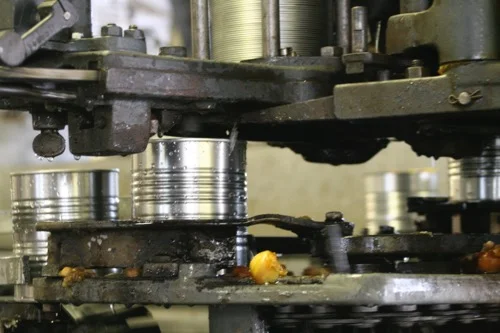

10. The cans are now ready to seal. They head single-file to the...

11. Seamer. This machine sets a lid on the top then rolls the edges of the can and lid together, forming a tight, squashed roll. The fresh fruit is now sealed inside and won't see the light of day until you open it for breakfast.

12. We no longer use this cooking process but this slice of history is too good to forget. The cans would travel up a conveyor into a cooker that was located in the ceiling of the cannery. They would run down the length, travel up to the next flight and run back to where they started. The speed of the belt determined the cook time. It was great in theory but the cans would often get stuck - usually in the middle of the cooker where you couldn't get to them - and the whole line would jam. If you couldn't find Russell during a canning day, you just needed to look near the cooker and there he'd be, lurking in the rafters with with a crowbar, ready to beat the cooker into submission.

Now the cans leave the seamer and go into a big metal basket that's lowered into hot water and timed with a kitchen timer. Much less exciting.

13. Finally the fruit which is now fully preserved comes out of the cooker and stacked by hand where they cool and wait to be labeled at a later date.

And THAT is how a cherry goes from bin to tin at our little cannery.